They can operate with either incompressible or compressible fluids as the primary driving and secondary driven flows. Converging Inlet Diffuser.

Gas Ejector Design Calculation.

. Track Test Results Maximum Draft at 12-14 kmhr Not measured assumed to be similar to case 3. Comparison of ejectors. Materials Inlet pipe Shell Paint Standard Other requirements BURSTING DISC EJECTOR Company Adress Department E-mail Your Ref Fonction Material Connection Suction Medium.

A study was performed to establish a simpler methodology for ejector design and for the prediction of performance based on the following. Transvac Engineers have designed a range of online software tools to enable our clients to run preliminary Ejector screening. Speaking for my experience with at least one of them they calculate a design and then make one and test it.

DESIGN CALCULATION FOR 2ND HOLDING. DESIGN P I D. With same ejector chimney but original sized single hole blast nozzle.

Basic design operating information and operation limitations of air ejectors. Fast cycle times possible. If it works as designed then they produce curves and that becomes the performance standard for that particular design.

The acceleration due to gravity is normally taken as 981 ms2. Experience from design. Free demo programs for a short time are offered to let you see how the ejector program works - they are not intended for your design work.

Ray Redline on Ejector Design Calculationpdf UPD. Published results by manufacturers. 10 degree taper Lempor Ejector with mixing chamber.

The measured ω for the ejectors used in the present study can reach as high as 054 at Pg 0465 MPa 84 C Pc. A study was performed to establish a simpler primary flow active gas. Pdf ejector design calculation xls ejector design calculation software steam ejector design calculation xls.

For suction pressures from 5 mm. The basic SI unit of force is the newton which has the symbol NOne newton is defined as the force necessary to give a mass of 1 kg an acceleration of 1 ms2. Low maintenance costs.

Gas ejector design can however be determined by rigorous calculation using the applicable equations 1 2. Up to 24 cash back Ejector Design Calculation Software Download. With Lempor Ejector as calculated by the spreadsheet without tuning.

By D Ekés 2015 Cited by 1 Abstract--In this paper I discussed the application and behaviour of jet ejectors and established a simple method for the calculation of the. Calculation example and an energy cost comparison following. Total inlet flow rate GPM LPM Number of eductors.

The Buss Reactor successfully used for hydroginations sulphonations animations etc. 2566 Yusuke Saito et al. Ejectors consist of six basic parts.

PHOTO PERFORMANCE TEST. Is designed on the former principle eg see van Dierendonck and Leuteritz 1988. Absolute to atmosphere the following equations will give approximate results for steam jet ejector stages handling air.

Published results by manufacturers. Ejectors or jet pumps utilize the pressure energy of a high-pressure fluid stream to boost the pressure andor flow of a low-pressure source. For many gasgas ejector applications encountered.

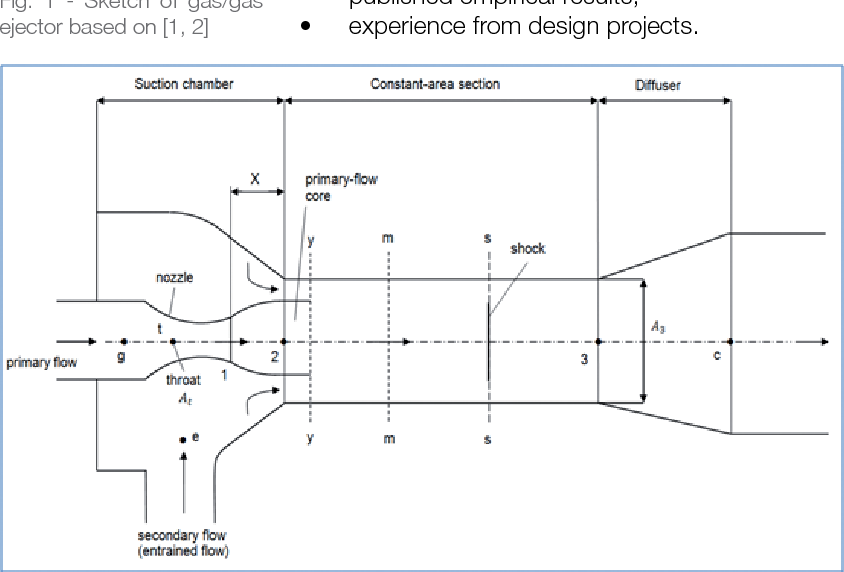

A study was performed to establish a simpler methodology for ejector design and for the prediction of performance based on the following. Up to 24 cash back Gas ejector design can however Ejector performance analysis be determined by rigorous calculation using the Figure 1 shows a sketch of gasgas ejector based applicable equations 1 2. For reporting bugs adding feature requests or submitting pull requests please use the GitHub issue tracker or contact the author at Caleb.

The ejector design principles used in the ejector calculations for the program are explained including the ejector energy balance and effects of the ejector flow cones. Published empirical results. Ejector design calculation ejector design calculation xls ejector design.

R141b is shown in the present study to be a good working fluid for an ejector. The high velocity primary stream is produced by expanding a high. Consult performance chart to select eductor size that best matches desired flow rate.

Ejector Design Calculation Pdf Downloadgolkes. Energy Procedia 57 2014 2564 2571 at a certain condition of a nozzle inlet pressure a generating pressure P g and a backpressure of the diffuser ie condensing pressure P cFigure 2R shows parameters of an ejector in the calculation. Ejector Design Calculation Pdf Download.

Jose Gonzales 02152020 0415PM. Gas ejector design can however be determined by rigorous calculation using the applicable equations 1 2. This is the acceleration imparted to a 1 kg force by its own weight 1 kg.

Calculation DN PN Allowed pressure drop Construction Materials Flanged Threaded. Up to 24 cash back A method of calculation for the ejector design using the correlations is also developed. Selection of Air Ejectors Part I.

The total inlet flow rate per eductor is. ComergingDiverging N ode 3. Motive Fluid Chest 2.

Jet Pump ejectoreductor Sizing and Rating fluidsjet_pump This module contains a model for a jet pump also known as an eductor or an ejector. Ejector Design Calculation Software Download Calculate Pump Head Required Watch on. In your case you have used very large ejector for your application that is why you need a high flow rate of motive gas in order to establish the required.

Up to 24 cash back Gas Ejector Design Calculation 125 X 276 345 kN for non-spring systems or 15 X 276 414 kN for spring return systems This demonstrates that the machine ejection force is satisfactory for the first case but unsatisfactory for the second case. PHOTO RAS-LAFFAN STEAM JET AIR EJECTORS. Up to 24 cash back Ejector Design Xls.

Ejector Technology at your fingertips. Blatchley Schutte Koerting An ejector is a pump which uses the jet action of one fluid to entrain and compress another fluid. Silencer Design Conditions Design flow rate Design temperature Design pressure.

Gas and Liquid-driven Ejector software is currently available online. Existing Locomotive believed true to original design. The applicable equations are provided by Huang et al 1 2 as follows.

There is a lot of an emperical component to vacuum jet design and manufacturing. 0087 MPa 28 C and Pe 0040 MPa 8 C. PHOTO NUEVA STEAM JET AIR EJECTORS.

Our aim is to make the technology more accessible to Engineers across the Oil Gas and process industries. The actual ejector designs can also be done for you based on the. Gas can either be recycled by using the suction characteristics of the ejector to draw gas back from the headspace of the vessel or operated in once-through mode.

This means that if you dont correctly designselect the optimum sizemodel in your sizing calculation you will end up with wrong results basically high or low motive gas flow rate. Eductors are usually spaced 1ft apart 1ft from the bottom and pointed in the desired flow direction.

A Method For Prediction Of Gas Gas Ejector Performance Pages 1 6 Flip Pdf Download Fliphtml5

Dagpiharca Ejector Design Calculationpdf Docker Image Docker Hub

Pdf A Method For Prediction Of Gas Gas Ejector Performance Semantic Scholar

A Method For Prediction Of Gas Gas Ejector Performance Pages 1 6 Flip Pdf Download Fliphtml5

Ejector Design Calculation Pdf

Ejector Design Calculation Ejector Dimensions Generate Ejector Curve

0 comments

Post a Comment